In the constant search for more efficient and sustainable solutions for construction, aerogels are emerging as a revolutionary technology in the field of thermal insulation.

What is aerogel?

It is an extremely light and porous material, created by replacing the liquid component inside a gel with gas. This process results in a solid structure with very low density and exceptional thermal properties. Also known as “solid smoke,” “frozen smoke,” or “blue smoke,” aerogel combines lightness with unprecedented insulating capacity.

The first aerogel was developed in 1931 by American scientist Samuel Kistler, who managed to replace the liquid in a gel with gas without collapsing its structure. In the 1960s, its use became popular in the aerospace sector as a thermal insulator. Since then, aerogels have evolved significantly, with advances in their manufacture and applications, especially in the field of thermal insulation.

Its main advantages

The use of aerogels in the construction sector offers multiple benefits:

- Energy efficiency: it provides extremely low thermal conductivity, much lower than that of conventional insulators, making it one of the best thermal insulators available. This translates into significant energy savings for buildings, by significantly reducing heating and cooling requirements.

- Sustainability: their use in construction promotes environmental sustainability. By reducing energy demand, CO2 emissions and carbon footprint are decreased.

- Lightness and strength: despite their fragile appearance, aerogels are surprisingly strong and can withstand significant loads. Their lightness makes them easy to handle and install in various construction applications without adding significant weight to the building structure, which is especially beneficial in construction projects where weight is a critical facto

- Fire resistance: Aerogels are non-combustible and can withstand extremely high temperatures, making them ideal for improving fire safety in buildings.

- Versatility in applications: They can be used in a wide variety of shapes and sizes, from rigid panels to flexible coatings, adapting to different construction needs.

Technical properties of aerogel

- Thermal conductivity: around 0.013 W/m·K, almost 5 times lower than the most effective polyurethane insulators.

- Density: 3 mg/cm³ or 3 kg/m³, being 1,000 times less dense than glass and three times denser than air.

- Porosity: more than 90% of its volume is composed of air.

- Fire resistance: it can withstand temperatures of up to 1,000 °C without degrading.

- Acoustic insulation: the speed of sound through aerogel is approximately 100 m/s.

- Refractive index: approximately 1.0, which gives it a transparency similar to that of air.

Which buildings have implemented this technology?

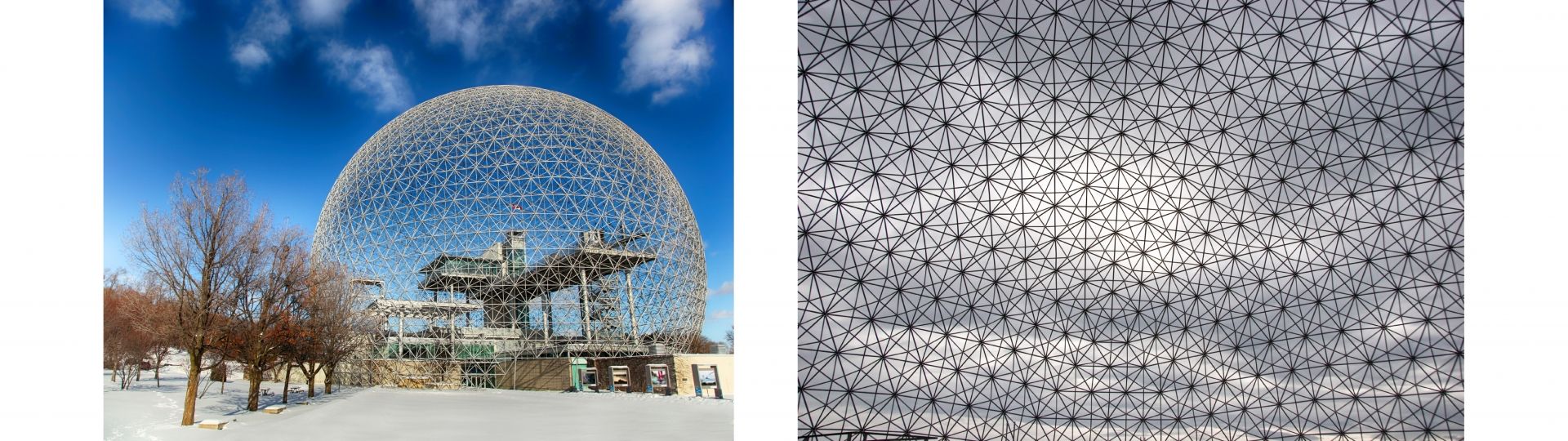

The Montreal Biosphere, designed in 1967 by visionary architect Richard Buckminster Fuller, stands as a symbol of sustainable architecture and an example of the potential of aerogel. This masterpiece, 76 metres in diameter, consists of an imposing steel structure that houses a museum inside. Its state-of-the-art thermal insulation is due to the innovative use of aerogel, a material that also allows natural light to enter.

Similarly, the Sculpture Building and School of Art Gallery at Yale University, designed by Kieran Timberlake and located in Connecticut (USA), has a spectacular translucent envelope covering nearly 6,000 m2, made of glass and aerogel.

Progress and future prospects

The powerful benefits of aerogel make it an undoubtedly promising material for the future of efficient and sustainable construction. Its market penetration is still limited due to its high cost, which is ten times higher than that of conventional insulation. However, ongoing research and technological developments are expected to overcome the current challenges and facilitate the take-off and widespread use of this innovative material.

In recent years, various research projects related to aerogel have been carried out, achieving significant advances and paving the way for its market penetration. Among these, we highlight HOMESKIN, a collaborative project funded by the European Union for the development of new products and construction solutions for thermal insulation in buildings, based on high-performance materials: AABC-Advanced Aerogel-based composite materials, with the aim of reducing the energy consumption of buildings, which currently accounts for 40% of global energy consumption, and CO2 emissions, which account for 36% of the total.

For its part, the VEEP (Versatile Eco-efficient Production) project, also funded by the European Union, has focused on developing high-quality, energy-efficient insulating coatings from aerogel particles and the reuse of waste generated by construction and demolition activities. Its aim has been to promote the circular economy and cost-effectively reduce the energy consumption of buildings.

At INCOGA, we are at the forefront of innovation. We are committed to constant innovation, conceiving the present and future of construction hand in hand with digitalisation and industrialisation, incorporating the latest technological advances in processes and materials into our methodology at an early stage.